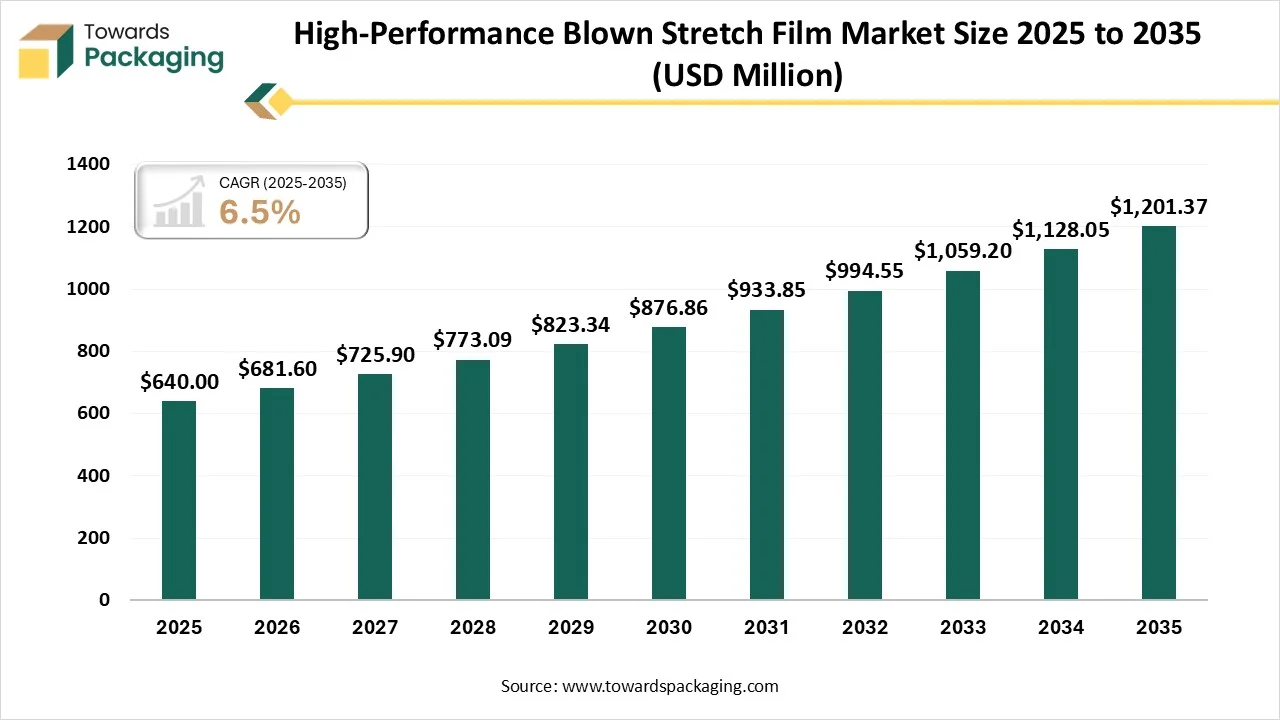

Ottawa, Feb. 11, 2026 (GLOBE NEWSWIRE) -- The global high-performance blown stretch film market reported a value of USD 640 million in 2025, and according to estimates, it will reach USD 1201.37 million by 2035, as outlined in a study from Towards Packaging, a sister firm of Precedence Research.

Request Research Report Built Around Your Goals: sales@towardspackaging.com

What is High-Performance Blown Stretch Film?

High-performance blown stretch film is a premium packaging material manufactured using the blown extrusion process, offering superior strength, puncture resistance, load stability, and cling compared to conventional stretch films. It enables secure pallet wrapping with reduced material usage. The high-performance blown stretch film market is driven by rising demand from logistics, e-commerce, and warehousing sectors, increased focus on load safety, cost efficiency, and growing adoption of sustainable, downgauged packaging solutions.

Get All the Details in Our Solutions - Access Report Sample: https://www.towardspackaging.com/download-sample/5955

Private Industry Investments for High-Performance Blown Stretch Film

- Berry Global's Circular Expansion: The company invested in its flexible films division to launch the Bontite Sustane line, which integrates 30% post-consumer recycled content without compromising puncture resistance.

- Cosmo First's Capacity Upgrade: A ₹400 crore investment was made to commission a new manufacturing line featuring advanced technology to boost the production of high-performance specialty packaging films.

- Jindal Poly Films' Advanced Lines: Through its subsidiary JPFL Films, the company committed over ₹700 crore toward new production lines in Nashik to scale global output of high-performance films.

- Ultimate Flexipack's MDO Integration: The firm invested in a sixth blown film line utilizing Machine Direction Orientation technology to create 100% recyclable PE laminates with superior structural properties.

- Antalis Sustainability Project: Investment was directed toward the Master'in Performance line, using high-grade polymer blends that allow for extreme downgauging while maintaining high load stability.

- S&K Technologies' Hygiene Facility: The company invested in specialized Varex II blown film technology equipped with defect detection to produce high-performance films for the medical and hygiene sectors.

Join now to access the latest packaging in industry segmentation insights with our Annual Membership: https://www.towardspackaging.com/get-an-annual-membership

What Are the Latest Key Trends in the High-Performance Blown Stretch Film Market?

1. Growing Emphasis on Sustainable Packaging Solutions

Manufacturers are increasingly focusing on developing environmentally responsible blown stretch films to align with sustainability goals and regulatory expectations. This includes reducing material usage through downgauging, incorporating recyclable structures, and using recycled content without compromising strength, load stability, or puncture resistance, making packaging operations more eco-conscious.

2. Continuous Advancements in Polymer and Resin Technologies

The market is seeing strong innovation in polymer science, with producers adopting advanced resin formulations to enhance film performance. These innovations help improve elasticity, tear resistance, and durability while allowing films to be thinner and lighter. As a result, companies can achieve cost efficiency and improved load protection simultaneously.

3. Rising Use of Automation-Compatible Films

As packaging and logistics operations become increasingly automated, demand is growing for high-performance blown stretch films that perform reliably on high-speed wrapping equipment. These films ensure consistent wrapping quality, reduce breakage, and support uninterrupted operations, making them suitable for modern distribution and warehouse environments.

4. Increased Focus on Manufacturing Efficiency and Process Control

Producers are investing in advanced manufacturing technologies to improve production efficiency and product consistency. Enhanced process monitoring, automation, and quality control systems help minimize defects, reduce waste, and ensure that films meet the strict performance standards required by industrial end users.

5. Custom-Engineered Films for Diverse End-Use Applications

There is a growing trend toward designing blown stretch films tailored to specific industry needs. These include films with enhanced cling, anti-slip properties, UV resistance, or specialized surface characteristics. Such customization helps industries like food, pharmaceuticals, and electronics achieve better load protection and handling performance.

6. Alignment with E-Commerce and Logistics Growth

The expansion of e-commerce and global logistics networks is driving demand for blown stretch films that provide superior load stability during long-distance transportation. High-performance films are increasingly preferred for their ability to secure irregular loads, reduce product damage, and improve overall supply chain efficiency.

What is the Potential Growth Rate of the High-Performance Blown Stretch Film Industry?

The high-performance blown stretch film industry is driven by expanding logistics and warehousing activities, rising e-commerce shipments, and the need for superior load stability during transportation. Growing adoption of automated wrapping systems, increasing demand for durable and puncture-resistant films, and a strong shift toward sustainable and downgauged packaging solutions are further supporting industry growth. Overall, the industry shows strong growth potential due to continuous material innovation and wider industrial usage.

Regional Analysis:

Who is the leader in the High-Performance Blown Stretch Film Market?

North America dominates the market due to strong demand from food, beverage, and e-commerce packaging, advanced manufacturing infrastructure, and rapid adoption of automation. Stringent packaging standards, focus on load stability and material efficiency, and continuous innovation by regional manufacturers further strengthen the region’s leadership.

U.S. High-Performance Blown Stretch Film Market Trends

In the U.S., demand for high-performance blown stretch film is driven by its dense warehousing networks, large palletized freight volumes, advanced automated wrapping systems, and strong logistics and e-commerce sectors. The food & beverage, consumer goods, and manufacturing industries further boost usage. Key trends include sustainability-focused material optimization (down-gauging, recycled content) and innovation in high-clarity, puncture-resistant films to meet regulatory and performance demands.

How is the Opportunistic is the Rise of the Asia Pacific in the High-Performance Blown Stretch Film Industry?

Asia-Pacific is the fastest-growing region in the market due to rapid industrialization, expanding manufacturing bases, and strong growth in e-commerce and logistics. Rising demand from food, beverage, and pharmaceutical packaging, increasing warehouse automation, and cost-efficient production capabilities further drive adoption. Additionally, growing investments in advanced packaging technologies and sustainability-focused material optimization support accelerated regional growth.

China High-Performance Blown Stretch Film Market Trends

China is expected to remain the dominant country in the Asia-Pacific market due to its large-scale manufacturing ecosystem, strong domestic consumption, and rapidly expanding logistics and warehousing sectors. High demand from food, beverage, and industrial packaging, along with cost-efficient production and faster adoption of advanced film technologies, continues to strengthen China’s regional leadership.

More Insights of Towards Packaging:

- North America Plastic Packaging Market Size, Trends and Segments (2026–2035)

- Biopolymer Packaging Market Size, Trends and Segments (2026–2035)

- Next-Generation Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- Recycled Materials Packaging Solutions Market Size and Segments Outlook (2026–2035)

- Commercial Printing Market Size, Trends and Competitive Landscape (2026–2035)

- Packaging Films Market Size and Segments Outlook (2026–2035)

- Contract Packaging and Fulfilment Services Market Size, Trends and Regional Analysis (2026–2035)

- Canada Pharmaceutical Packaging Market Size, Trends and Segments (2026–2035)

- South Korea Cosmetic Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- Germany Flexible Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- U.S. Cosmetic Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- U.S. Pharmaceutical Packaging Market Size, Trends and Regional Analysis (2026–2035)

- U.S. Glass Packaging Market Size and Segments Outlook (2026–2035)

- Flexible Packaging Adhesive Market Size, Trends and Regional Analysis (2026–2035)

- France Pharmaceutical Packaging Market Size, Trends and Regional Analysis (2026–2035)

- Japan Packaging Machinery Market Size, Trends and Competitive Landscape (2026–2035)

- Repackaging Service Market Size and Segments Outlook (2026–2035)

- Corrugated Automotive Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- Barrier-Coated Flexible Paper Packaging Market Size, Trends and Regional Analysis (2026–2035)

- Bio-Based Packaging Market Size, Trends and Competitive Landscape (2026–2035)

Segment Outlook

Film/ Product Type Insights

How Blown Stretch Film Segment Dominates the High-Performance Blown Stretch Film Market?

The blown stretch film segment holds the dominant position in the market due to its excellent puncture resistance, superior load containment, and high tear strength. It is widely used for packaging heavy, sharp, and irregular loads, ensuring stability during storage and transportation. Its consistent performance, durability, and suitability for demanding logistics environments make it extensively preferred across industries.

The cast stretch film segment is the fastest-growing in the market due to its clarity, smooth surface, and exceptional cling properties. It allows for easy manual and machine application, reduces material usage, and provides consistent load stability. These features make it ideal for packaging delicate, lightweight, or high-value products, driving rapid adoption across industries.

Material Type Insights

Which Material Type Dominated the High-Performance Blown Stretch Film Market?

The linear low-density polyethylene (LLDPE) segment dominates the market due to its excellent strength, flexibility, and puncture resistance. LLDPE offers superior load containment, stretchability, and clarity, making it suitable for a wide range of packaging applications. Its cost-effectiveness, durability, and compatibility with both manual and automated wrapping systems drive widespread adoption across industries.

The metallocene polyethylene (mPE) segment is the fastest-growing material type in the market due to its superior strength, elasticity, and puncture resistance compared to conventional LLDPE. It enables thinner films with enhanced load stability, reduces material usage, and improves performance for heavy or irregular loads, driving rapid adoption across packaging and logistics applications.

End-Use Insights

Which End-use Segment is Dominant in the High-Performance Blown Stretch Film Market?

The industrial & manufacturing segment dominates the market due to its extensive use in securing heavy, bulky, and irregular loads during storage and transportation. High demand from automotive, machinery, and electronics industries, combined with the need for efficient palletization, load stability, and protection against damage, drives widespread adoption of blown stretch films in this segment.

The e-commerce & retail segment is the fastest-growing in the market due to the surge in online shopping and home delivery services. High demand for secure, lightweight, and tamper-resistant packaging, combined with the need for efficient palletization and protection of diverse consumer goods, is driving rapid adoption of advanced stretch films in this sector.

Recent Breakthroughs in the High-Performance Blown Stretch Film Industry

- In December 2025, Cortec Corporation, a manufacturing company, launched the EcoSonic VpCI‑125 HP, a high-performance blown stretch film specifically designed for electronics packaging. This innovative film provides continuous protection against electrostatic discharge (ESD) while also preventing corrosion over the product’s entire lifespan.

- In October 2025, Braskem, a market leader in industrial biopolymer production, is presently in Düsseldorf, Germany for K 2025, the world's premier plastics and rubber trade show. Braskem presented a new range of circular and bio-based product solutions on the opening day to quicken the plastics industry's transformation. This included collaborations with Dutch companies Eurobottle and Bottle Up.

Elevate your packaging strategy with Towards Packaging. Enhance efficiency and achieve superior results - schedule a call today: https://www.towardspackaging.com/schedule-meeting

Top Companies in the Global High-Performance Blown Stretch Film Market & Their Offerings:

Tier 1:

- Berry Global Group, Inc.: Offers the Bontite range, a high-performance blown film engineered for extreme puncture resistance and heavy load containment.

- Amcor plc: Provides high-performance blown films designed for superior load stability and high pre-stretch capabilities to reduce material usage.

- Sealed Air Corporation: Specializes in advanced flexible blown films that prioritize high-strength protection and durability for demanding industrial applications.

- AEP Industries Inc.: Manufactures the Performance Plus series, a heavy-duty blown film known for its toughness and ability to secure irregular loads.

- Sigma Plastics Group: Produces specialized blown stretch films through its Sigma Stretch division, focusing on high cling and tear resistance for versatile palletizing.

- Intertape Polymer Group Inc.: Supplies high-performance blown films that offer exceptional holding power and reliability for securing heavy or sharp-edged shipments.

Tier 2:

7. Coveris Holdings S.A.

8. Mondi Group

9. RKW Group

10. Trioplast Industrier AB

11. Paragon Films Inc.

12. DUO PLAST AG

13. Polifilm GmbH

14. Manuli Stretch S.p.A.

15. Integrated Packaging Group Pty Ltd

16. Eurofilms Extrusion Ltd

17. FlexSol Packaging Corp.

18. Bolloré Group

19. Novolex

20. Hilex Poly Co., LLC

21. Inteplast Group

22. Plastiflex Inc.

23. Scientex Berhad

24. Anchor Packaging Inc.

Segment Covered in the Report

By Film / Product Type

- Blown Stretch Film

- Standard Blown Film

- Multi-layer Blown Film

- Antibacterial / Food-Grade Blown Film

- Cast Stretch Film

- Standard Cast Film

- Multi-layer Cast Film

- Transparent / Clear Cast Film

- Pre-stretch Film

- Hand Pre-Stretch Film

- Machine Pre-stretch Film

- Colored / Printed Pre-stretch Film

- Machine Stretch Film

- Coreless Machine Film

- Center-Wound Machine Film

- Edge Reinforced Machine Film

- Hand Stretch Film

- Standard Hand Film

- Colored / Printed Hand Film

- Ultra-Stretch Hand Film

- Specialty Stretch Film

- Anti-Static Film

- Food-Grade Film

- Anti-Slip Film

- Barrier Stretch Film

- Moisture Barrier Film

- Oxygen Barrier Film

- Light-Barrier Film

- UV-Resistant Stretch Film

- Outdoor UV-Resistant Film

- Colored UV Film

- UV-Protective Barrier Film

- Reinforced / High-Strength Film

- Fiberglass Reinforced Film

- Woven / Mesh Reinforced Film

- High-Tensile Strength Film

By Material Type

- Linear Low-Density Polyethylene (LLDPE)

- Metallocene Polyethylene (mPE)

- Low-Density Polyethylene (LDPE)

- High-Density Polyethylene (HDPE)

- Polypropylene (PP)

- Polyvinyl Chloride (PVC)

- Other Polymer Blends

By End-Use Industry

- Industrial & Manufacturing

- E-commerce & Retail

- Food & Beverage

- Pharmaceuticals & Healthcare

- Consumer Goods

- Automotive

- Textile & Apparel

- Chemical & Petrochemical

- Electronics

- Agriculture

By Region

North America:

- U.S.

- Canada

- Mexico

- Rest of North America

South America:

- Brazil

- Argentina

- Rest of South America

Europe:

- Western Europe

- Germany

- Italy

- France

- Netherlands

- Spain

- Portugal

- Belgium

- Ireland

- UK

- Iceland

- Switzerland

- Poland

- Rest of Western Europe

Eastern Europe

- Austria

- Russia & Belarus

- Türkiye

- Albania

- Rest of Eastern Europe

Asia Pacific:

- China

- Taiwan

- India

- Japan

- Australia and New Zealand,

- ASEAN Countries (Singapore, Malaysia)

- South Korea

- Rest of APAC

MEA:

- GCC Countries

- Saudi Arabia

- United Arab Emirates (UAE)

- Qatar

- Kuwait

- Oman

- Bahrain

- South Africa

- Egypt

Invest in Our Premium Strategic Solution: https://www.towardspackaging.com/checkout/5955

Request Research Report Built Around Your Goals: sales@towardspackaging.com

About Us

Towards Packaging is a global consulting and market intelligence firm specializing in strategic research across key packaging segments including sustainable, flexible, smart, biodegradable, and recycled packaging. We empower businesses with actionable insights, trend analysis, and data-driven strategies. Our experienced consultants use advanced research methodologies to help companies of all sizes navigate market shifts, identify growth opportunities, and stay competitive in the global packaging industry.

Stay Connected with Towards Packaging:

- Find us on Social Platforms: LinkedIn | Twitter | Instagram | Threads

- Subscribe to Our Newsletter: Towards Sustainable Packaging

- Visit Towards Packaging for In-depth Market Insights: Towards Packaging

- Read Our Printed Chronicle: Packaging Web Wire

- Get ahead of the trends – follow us for exclusive insights and industry updates:

Pinterest | Medium | Tumblr | Hashnode | Bloglovin | LinkedIn – Packaging Web Wire | Globbook | Substack | Bluesky | Justdial | Crunchbase | TrustPilot | Bizcommunity - Contact: APAC: +91 9356 9282 04 | Europe: +44 778 256 0738 | North America: +1 8044 4193 44

Our Trusted Data Partners

Precedence Research | Towards Healthcare | Towards Food and Beverages | Towards Chemical and Materials | Healthcare Webwire | Packaging Webwire | Precedence Research Insights

Towards Packaging Releases Its Latest Insight - Check It Out:

- Active and Intelligent Packaging Market Size and Segments Outlook (2026–2035)

- Plain Packaging Market Size, Trends and Regional Analysis (2026–2035)

- Packaging Waste Management Market Size, Trends and Competitive Landscape (2026–2035)

- Track and Trace Packaging Market Size, Trends and Segments (2026–2035)

- Single-Use Plastic Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- Unbleached Kraft Paperboard Market Size, Trends and Segments (2026–2035)

- Egg Boxes and Trays Market Size and Segments Outlook (2026–2035)

- Corrugated Packaging for Pharmaceutical Market Size, Trends and Competitive Landscape (2026–2035)

- Germany E-Commerce Packaging Market Size and Segments Outlook (2026–2035)

- Corrugated Box Packaging for Electronics Market Size, Trends and Regional Analysis (2026–2035)

- Reusable Cold Chain Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- Polypropylene Corrugated Packaging Market Size, Trends and Competitive Landscape (2026–2035)

- North America Packaging Tape Printing Market Size and Segments Outlook (2026–2035)

- Europe Fresh Food Packaging Market Size and Segments Outlook (2026–2035)

- Packaging Tape Printing Market Size and Segments Outlook (2026–2035)

- Unit Dose Packaging Market Size, Trends and Regional Analysis (2026–2035)

- North America High-Barrier Packaging Films Market Size, Trends and Segments (2026–2035)

- Corrugated Boxes for Transit Packaging Market Size, Trends and Regional Analysis (2026–2035)

- Carbonated Soft Drinks (CSD) Packaging Market Size, Trends and Segments (2026–2035)

- Personalized Packaging Market Size, Trends and Segments (2026–2035)